Information

We combine biology and engineering

Fraunhofer IGB develops and optimizes processes, technologies and products for health, sustainable chemistry and the environment. In doing so, we rely on the combination of biological and process engineering competencies to develop solutions for patient-tailored health care, a sustainable bioeconomy and climate-neutral as well as resource-efficient circular economy. We offer our customers research services from feasibility studies to application-ready development, complemented by a wide range of analytical and testing services. Complete solutions from laboratory to pilot scale are one of the strengths of the institute.

Services

Sustainable chemistry – Developing and scaling up processes for the production of sustainable chemicals, fuels and materials from biogenic raw/waste materials or CO2

The Sustainable Chemistry business area provides solutions for ways of doing business that are not only economic but also more ecological. Our prime objective is to develop synthesis processes that are highly efficient – in terms of both energy and resources – and based on renewable raw materials, biogenic waste materials or carbon dioxide, coupled with intelligent solutions for work up the resulting products.

Fraunhofer IGB is active in the development of:

- Pretreatment and fractionation processes for raw materials

- Industrial biotechnology processes for selectively converting materials by means of enzymatic or fermentation processes

- Chemocatalytic, electrochemical and electrobiological processes and their combination with biotechnological processes

- Power-to-X processes for the utilization of regenerative produced redox equivalents in synthesis processes

- Customized thin films and functionalized surfaces

Fraunhofer IGB is helping to drive the transformation of the process industry, especially in the chemicals sector, and contributes to all four segments of the bioeconomy: food, animal feed, sustainable chemical products and bioenergy.

Environment – Sustainable resource management for industry, municipal authorities and agriculture

At Fraunhofer IGB in the business area Environment, systemic solutions are developed that provide integrated environmental protection for industry as well as for city and regional authorities, both in Germany and abroad. Our activities in this field comprise the development of new ideas and processes as well as individual solutions and products. Our aim is to achieve the greatest possible efficiency in the use of resources by following the concepts of the circular economy and sustainability.

Fraunhofer IGB is active in the development of:

- Innovations and solutions in water management and water treatment

- Processes for generating biogas from organic waste and residues

- Solutions that recover and reclaim nutrients from wastewater, organic waste and residues

- Processes for drying/torrefaction of organic waste fractions to produce soil conditioners

- Separation processes on the molecular and atomic level for the recovery of precious metals, and rare earth compounds

With our biological and biotechnological developments, further empowered by the latest digital innovations, Fraunhofer IGB drives innovation in environmental technology and the industrial transformation towards a sustainable and circular bioeconomy.

Products

Water- and energy management

Fraunhofer IGB has developed technologies that enable both cost-effective and efficient water management in urban structures through decentralized treatment of water and wastewater flows. We thus offer system solutions for sustainable municipal water management in rural regions, new development areas, urban districts in need of redevelopment, and also for leisure resorts, tourist centers and hotel complexes.

High-load digestion – Efficient process for the digestion of sewage sludge and organic substrates into biogas

We have already implemented the efficient production of biogas from sewage sludge using our high-load digestion process at various municipal sewage treatment plants. Through high-load digestion, the sewage sludge is stabilized with net energy gain, can be optimally dewatered and thermally disposed of at the lowest possible cost. The regenerative energy source biogas is produced as a product. With the biogas obtained, the energy requirement of the sewage plant can be covered and thus further costs can be saved. High load digestion is therefore also an intelligent alternative from an economic point of view and significantly improves the energy efficiency of municipal sewage treatment plants. We also develop specific solutions for the conversion of biowaste to energy. These range from fermentation tests to the design of plants on a technical scale and the optimization of agricultural biogas plants in terms of productivity and efficiency.

Water treatment using advanced oxidation processes (AOP)

Oxidative processes offer effective and sustainable solutions for water treatment. Oxidative water treatment (Advanced Oxidation Processes, AOP) comprises chemical treatment processes in which hydroxyl radicals are formed. At our research facility, we develop optimized oxidative processes for customers. The modular units (ozone generator, ozone reactor, UV reactor, ultrasonic units, electrolysis cell) can be freely combined.

BioEcoSIM® – Combined process for the treatment of manure and digestate

Manure and digestate contain valuable plant nutrients, especially nitrogen, phosphorus and potassium; indigestible plant fibers are further components. In the BioEcoSIM project, which was funded by the EU and coordinated by Fraunhofer IGB, various processes for treatment were developed and the individual process stages were combined in a plant on a demonstration scale. This turns waste and residual materials into valuable raw materials and closes the natural nutrient cycle. A first fully automated processing plant with a throughput of one cubic meter per hour was built and tested at the SUEZ site in Zorbau, Saxony-Anhalt. The flexibly designed plant is intended to process cattle and pig manure, but also digestate from biogas plants, and serve as a blueprint for further large-scale plants.

Projects

HypoWave – Water reuse in agriculture

Regional competition for water resources is not uncommon. Due to climate change, urbanization and pollution of water resources, conflicts over use could become even more acute in the coming decades. Therefore, new processes for water treatment and water reuse make sense. In the "HypoWave" project, funded by the German Federal Ministry of Education and Research (BMBF), a water-saving concept for agriculture was investigated: Hydroponic crop production, with irrigation derived from municipal wastewater. How the concept can be implemented in each case was determined in case studies at four different locations in Germany, Belgium and Portugal.

As part of the piloting of the overall system, the IGB used an EGSB reactor developed by partner ACS-Umwelttechnik GMBH & Co. KG, an EGSB reactor (Expanded Granular Sludge Bed) for the anaerobic pre-treatment of municipal wastewater. Here, organic impurities were converted into biogas as an energy source, while the nutrients required as fertilizer for the plants in the hydroponic system were retained. An overarching control system for the pilot plant allows the individual modules for wastewater treatment and plant production to communicate with each other.

Hydrofichi – Chitosan-based hydrophobic and soil-repellent finishing of textiles to substitute perfluorinated chemicals (PFCs)

The aim of the Hydrofichi project was to modify textile surfaces using renewable raw materials in order to replace environmentally harmful and toxic agents previously used. For this purpose, a chitosan-based hydrophobic finishing of textiles was developed. This can replace toxic and petroleum-based substances currently used for textile finishing. Fraunhofer IGB and its partners researched how this can work in the HydroFichi project: a technology was developed to give fibers the desired properties with the help of biotechnological processes and chitosan.

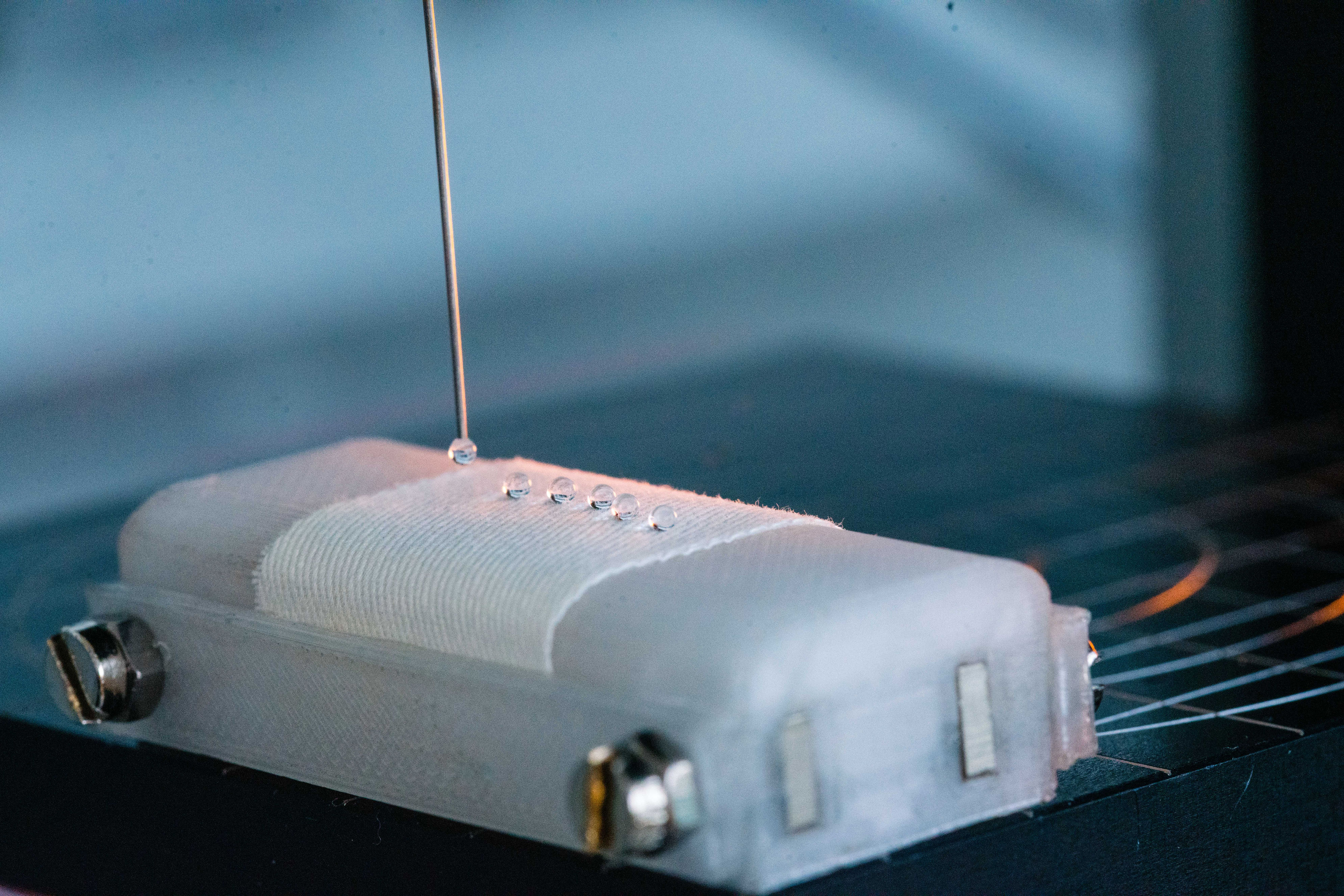

Celbicon – Cost-efficient conversion of carbon dioxide into chemicals

Time is pressing in climate protection. One possible solution is to use the greenhouse gas CO2 as a raw material for chemicals. To this end, the Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB, together with partners from science and industry, has pursued a new approach in the EU-funded CELBICON project. By combining electrochemical and biotechnological conversion, the researchers succeeded in producing a value-adding terpenoid dye from the greenhouse gas adsorbed from air.

Markets

Contact

Fraunhofer-Institut für Grenzflächen- und Bioverfahrenstechnik IGB

Fraunhofer-Institut für Grenzflächen- und Bioverfahrenstechnik IGB

Nobelstraße 12

70569 Stuttgart

Germany

More locations

Fraunhofer-Institut für Grenzflächen- und Bioverfahrenstechnik IGB is responsible for the content of this company profile as well as the compliance with the copyrights of the image material.